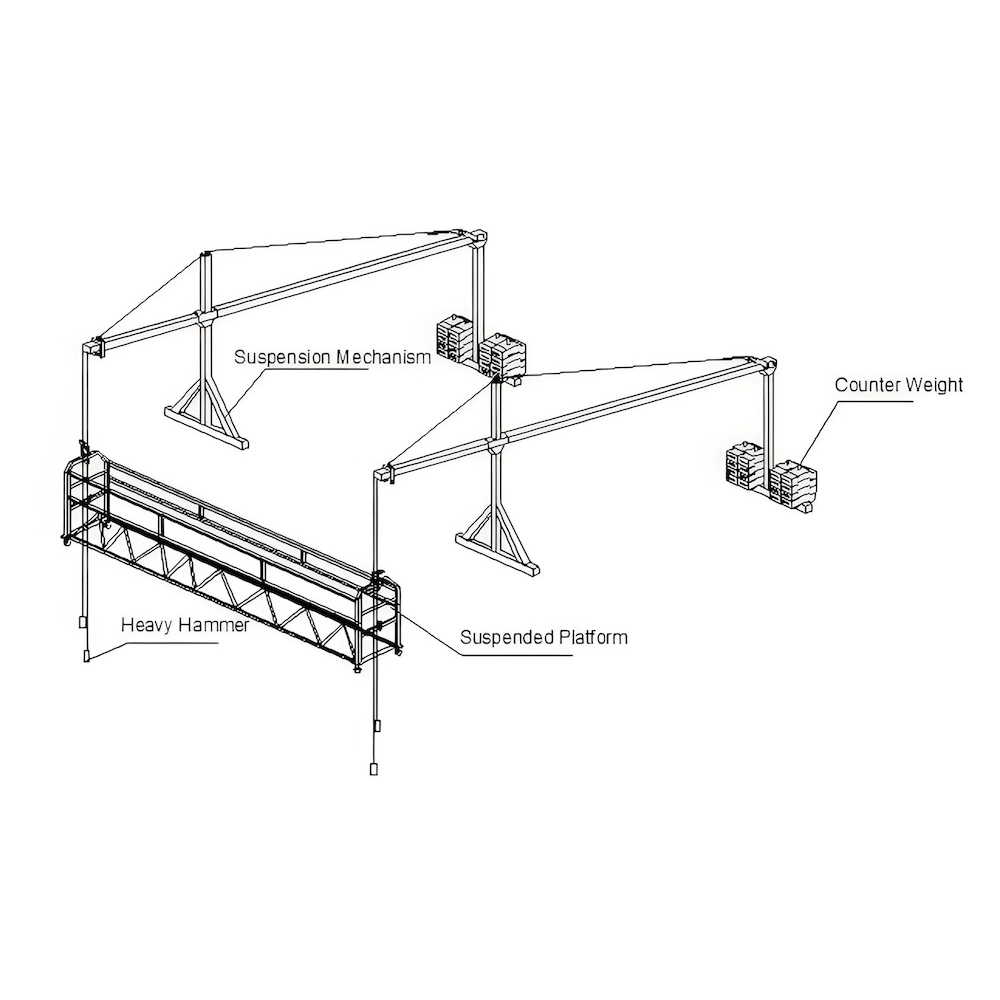

1. Suitable for all suspended baskets and roof structures, with rear pressure counterweights;

2. The rear hanging design of the steel wire rope improves the force condition of the cantilever, making it easy and safe to retract and release the steel wire rope;

3. Height adjustable, cantilever extension adjustable: 700mm~1500mm.

Clamp type suspension mechanism for parapet wall:

1. Simple structure, no need for counterweights, easy installation, convenient transportation, saving labor and costs;

2. Mainly suitable for buildings or structures with high strength;

3. According to user needs, an independent safety rope hanging bracket for parapet installation can also be provided.

Safety rules

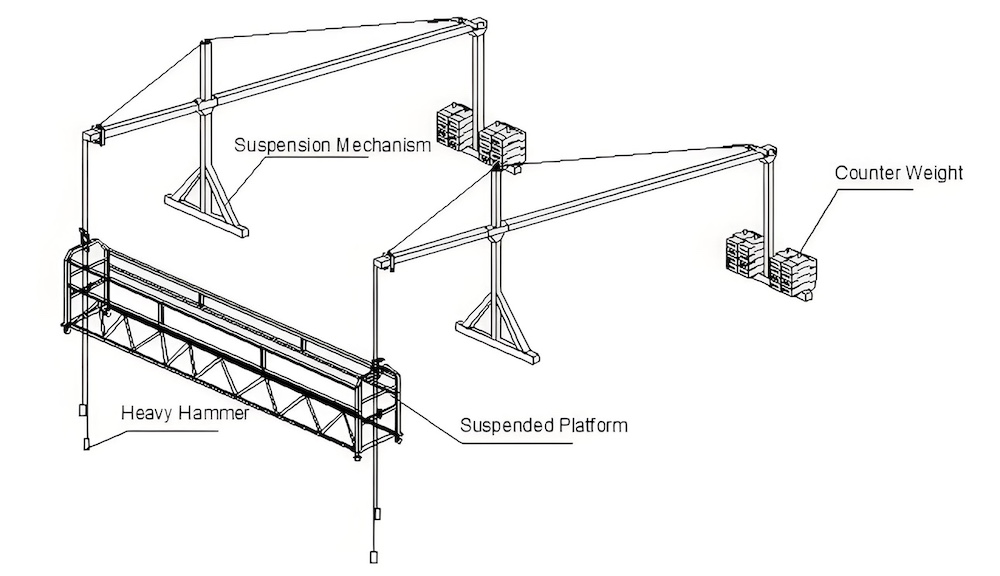

1. When installing the ground, a horizontal surface should be selected. If there is a slope, it should be reliably leveled under the corner wheel. If the installation surface is a waterproof and insulation layer, a 2.5-3cm thick wooden board should be added under the front and rear seats to prevent damage to the waterproof and insulation layer.

2. The adjustment support height of the adjustable suspension bracket should be slightly higher than the height of the parapet wall on the lower side of the front beam

3. The rated adjustment range for the overhanging length of the front beam end is 0.3~1.5 meters. When exceeding the rated overhang length, reliable reinforcement measures and rated working load must be taken.

4. The distance between the front and back seats should be adjusted as much as possible to the maximum distance allowed by the venue.

5. The distance between the two brackets should be adjusted to be 3-5 centimeters smaller than the length of the suspension platform between the overhanging endpoints of the front beam.

6. When tensioning and strengthening the steel wire rope, the front beam should be slightly raised by 3-5 centimeters to generate prestress and increase the rigidity of the front beam.